A TQA VITTA, specialist in this segment, develops rubber compounds to guarantee the protection of metal and concrete structures, machines and equipment, exposed to corrosive and abrasive attacks according to ASTM standards, which guarantees the quality demanded by its customers.

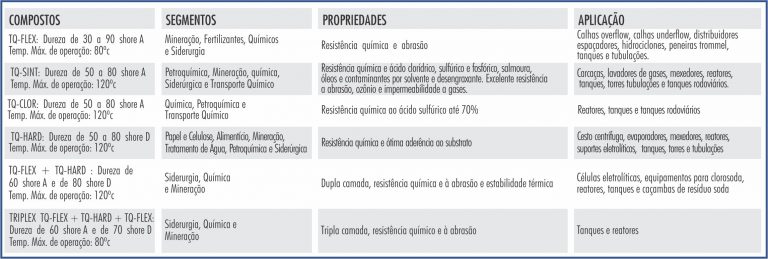

The compounds are developed based on Natural Rubber, Common and Graphite Ebonite, Hypalon, Clorobutyl, Neoprene, Nitrile, EPDM e SBR.

TQA offers a line of anti -bristle and anti -corrosion rubber compounds to the entire market with full efficiency for permanent coatings and repairs on equipment in general.

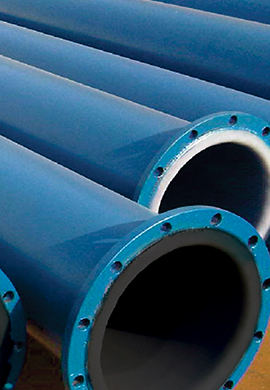

In addition to anticorrosive coatings, We make a new product line available to the entire market: composite material with total efficiency in permanent repair for rehabilitation of ducts and pipes. Request more information.